Posts Tagged ‘thermoplastic peek’

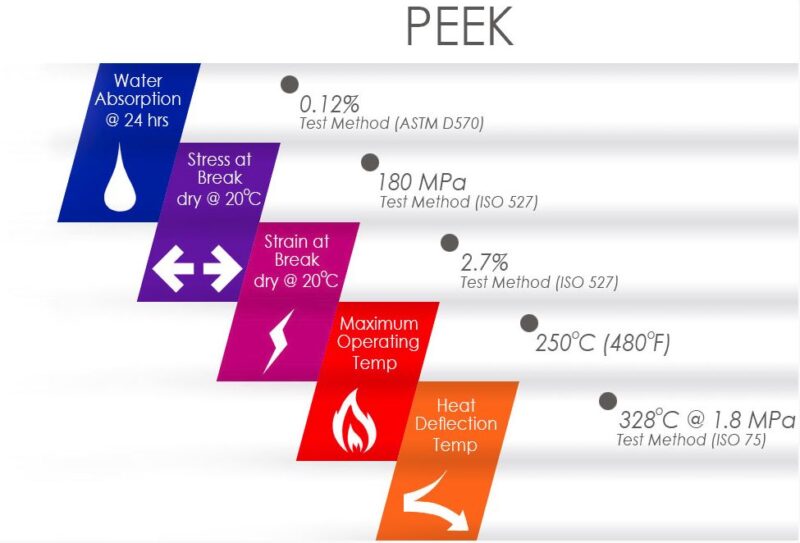

Why Thermoplastic PEEK is the Industry Leader

Thermoplastic PEEK is included in a variety of specific products and industries. Why is it so important? Read further to find all the details you should know. PEEK is the common name for Polyetheretherketone and refers to a semi-crystalline organic polymer. This type of thermoplastic is highly stable which makes it far superior to many…

Read MoreAn Overview of PEEK Material and Its Important Uses

You may know the basics of PEEK material, but what about its uses in our everyday life? To gain a better understanding, read the important details below. The formation of systems transforms every day with new technological innovations being introduced into the engineering industry. Scientists, engineers, and all come up with a different hypothesis to…

Read MoreThe Important Role of PEEK Plastic in Medical Equipment

When it comes to manufacturing various types of medical equipment, the role of PEEK plastic is quite essential. Read the interesting facts below. Have you ever wondered why polyether ether ketone (PEEK) is so popular in medical device manufacturing companies and healthcare centers? If yes, keep reading as this article will reveal to you the…

Read More7 Reasons to Consider PEEK Thermoplastic Parts

There are several reasons why you should consider PEEK Thermoplastic for parts despite the wide range of materials you can choose from, here are 7 of the most popular reasons. PEEK, for instance, takes it one step further by ensuring that your thermoplastic parts can stand the test of time and are not easily inflammable.…

Read MoreThe Benefits of Thermoplastic PEEK

Are you looking for an extremely durable and lighter weight material to use in machine parts? Thermoplastic PEEK is the dependable solution that you are looking for. Considered a high performance thermoplastic, PEEK is the acronym used for polyether ether ketone, a thermoplastic material with a wide range of uses in a wide variety of…

Read MoreThe Beauty of Thermoplastic Compressor Rings

Manufacturing high-quality compressor components is both an art and a science. Compressor rings are integral parts for any compressor. Metal rings have a long history, but advances have been made in developing other strong, durable materials that can withstand harsh operating conditions. Modern thermoplastics offer an attractive alternative to metal rings, and in the long…

Read MoreCompressor Valve Plates Manufactured for Durability

In order for a compressor valve to function at its maximum efficiency, each of its individual components must be well-constructed. This includes the sealing components, which in certain types of compressor valves are the valve plates. Carefully manufactured compressor valve plates perform better for longer periods of time. Metals and thermoplastics each have advantages…

Read MoreThe Importance of Profile Rings

Profile rings are used in compressors to provide a tight seal to insulate steam, liquids and gases and prevent them from escaping. Preventing leakages is essential to the continued function of any compressor. When a profile ring becomes damaged or worn out, you may notice odd noises that eventually will signal a lessening in…

Read MoreChoosing the Right Valve Plate

The valve plate is an essential part of the valve assembly and act as a seal between different areas in the compressor. Because valve plates can be exposed to a punishing variety of pressures, temperatures, and chemicals, they need to be made of materials that can withstand the stress that they go through every time…

Read MoreShould You Use Metal or Thermoplastic Valve Plates?

Compressor valve plates will need to be replaced eventually because they handle a lot of wear and tear. When worn plates are swapped out for new ones, you might notice quite a boost in the power capacity of the machine and some of the problems that had begun to appear may be resolved. As you…

Read More