Thermoplastic Parts

An Overview of PEEK Material and Its Important Uses

You may know the basics of PEEK material, but what about its uses in our everyday life? To gain a better understanding, read the important details below. The formation of systems transforms every day with new technological innovations being introduced into the engineering industry. Scientists, engineers, and all come up with a different hypothesis to…

Read MoreThe Important Role of PEEK Plastic in Medical Equipment

When it comes to manufacturing various types of medical equipment, the role of PEEK plastic is quite essential. Read the interesting facts below. Have you ever wondered why polyether ether ketone (PEEK) is so popular in medical device manufacturing companies and healthcare centers? If yes, keep reading as this article will reveal to you the…

Read MoreDeciding Whether or Not You Need a Thermoplastic Plate

If you’re questioning your need for a thermoplastic plate, it’s best to first understand all the details about it. Read below for information that can help you make a solid decision. If you’re at the point of deciding whether you need a thermoplastic plate for your machine, the most advantageous method to help you make…

Read MoreYour Guide to the Types of Plastic Molding

It’s always great to be aware of the types of plastic molding, which all include some advantages and disadvantages. Choose what’s best for your product needs. Read the details below. There are different types of plastic molding and each is best suited for the end-product that is expected. Therefore, your choice of which should be…

Read MoreTypes of O-Ring Seals: What You Need to Know

How much do you know about the types of O-ring seals, specifically profile rings? It’s ideal to gain more knowledge or refresh your memory. Below, you’ll find more details about its benefits. In the industry world, there are many different parts and equipment that each play a vital role in the operation of a machine.…

Read More4 Tips for Injection Molding Design

It’s important to understand what goes into the injection molding design process if you want to create the best products. The little details count! Focus on these helpful tips below. The tips for injection molding design are important, hence, they need your utmost consideration. Why’s that? You may wonder. But the reason is not farfetched.…

Read More6 Reasons To Consider Nylon Plastic Injection Molding

Do you know what makes nylon plastic injection molding so useful and effective? Its due to its beneficial properties and unique materials. Read below for the details on why it’s a good choice. There are several reasons to consider Nylon Plastic (PA) injection molding due to the benefits offered by these materials. These benefits stem…

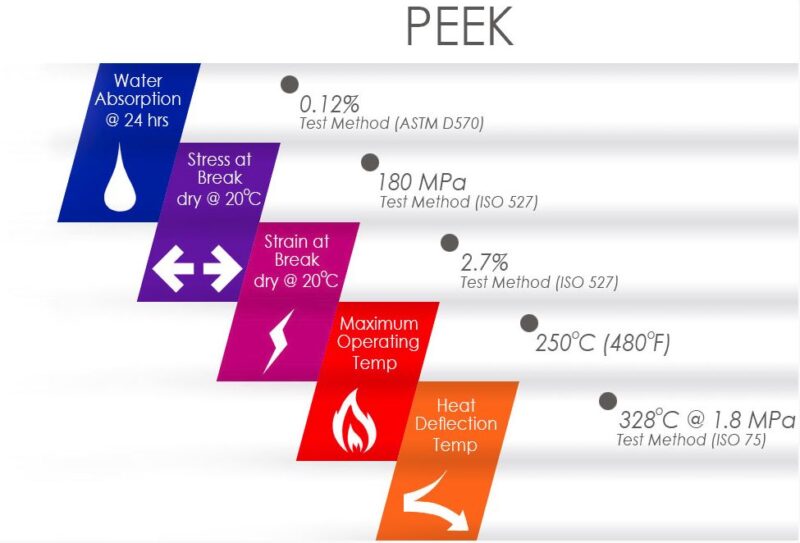

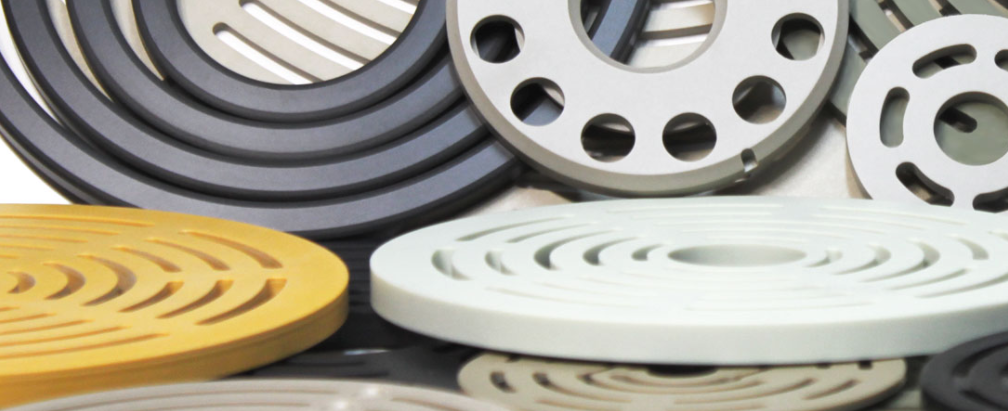

Read More7 Reasons to Consider PEEK Thermoplastic Parts

There are several reasons why you should consider PEEK Thermoplastic for parts despite the wide range of materials you can choose from, here are 7 of the most popular reasons. PEEK, for instance, takes it one step further by ensuring that your thermoplastic parts can stand the test of time and are not easily inflammable.…

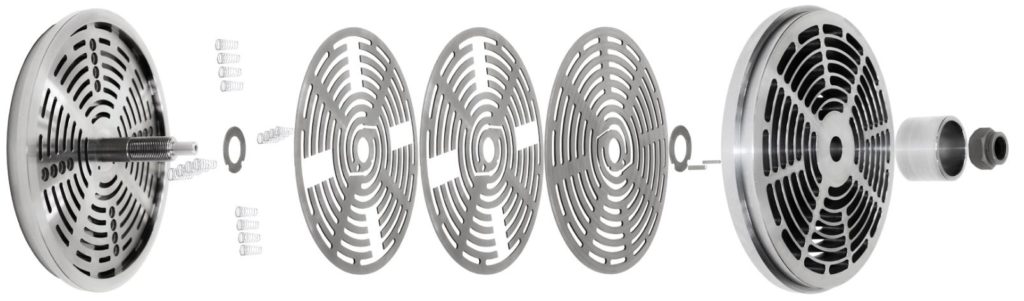

Read MoreTypes of Piston Rings and Their Importance

Some are surprised to learn there are multiple types of piston rings when it comes to PET compressors – and they each serve their own purpose. When a PET compressor does not function properly, the rest of the system suffers. Staff members are not able to perform their functions, productivity takes a hit, and repairs…

Read MoreWhat Are the Types of Thermoplastics and Their Uses?

Thermoplastics are used in a wide variety of industries for all types of different products; but what are the different types of thermoplastics and their uses? Thermoplastics are highly versatile materials which are made from polymers. A polymer is constructed of monomers, or tiny molecules which are electrically joined. When a thermoplastic is formed, it…

Read More