PET Plastics

How a P.E.T. Compressor Works, and Key Valve Parts to Stock

A P.E.T. compressor is designed to efficiently compress gases for industrial applications, ensuring consistent pressure and reliable operation. Its performance depends on well-maintained components, particularly valves, which control gas flow during compression cycles. Proper maintenance and stocking of key parts enhance durability, reduce downtime, and optimize system efficiency. Understanding how a P.E.T. compressor operates is…

Read MoreBlow Molding Products: Innovating with Custom Designs and Materials

Blow molding products offer exceptional flexibility in design and material selection, making them ideal for creating custom, high-performance items across industries. From packaging to medical applications, this manufacturing process enables precise, lightweight, and durable products that meet specific needs. Innovation in blow molding continues to drive efficiency and product customization. In today’s fast-paced manufacturing environment,…

Read MoreWhat Is PET Material? Exploring Its Properties and Applications

What is PET material? PET (Polyethylene Terephthalate) is a strong, lightweight, and recyclable plastic widely used in packaging, textiles, and industrial applications. Known for its durability, clarity, and resistance to moisture, PET is a preferred choice for food containers, beverage bottles, and synthetic fibers. Its recyclability makes it an environmentally friendly option in various industries.…

Read MoreSustainability in the P.E.T. Bottle Blowing Industry: Challenges and Opportunities

The P.E.T. bottle blowing industry plays a crucial role in producing lightweight, durable, and recyclable plastic bottles for beverages and other consumer goods. This industry focuses on efficiency and sustainability, using advanced technologies to mold P.E.T. (Polyethylene Terephthalate) into bottles, while also addressing environmental concerns through recycling and innovative manufacturing processes. The P.E.T. bottle blowing…

Read MoreWhat Makes Polyethylene Terephthalate (PET) Such a Durable Plastic?

Delve into the science behind PET, examining its chemical composition and physical properties that make it such a durable plastic. We also discuss the various applications of PET, its environmental impact, and how advancements in PET recycling are helping to make it a more sustainable material. Polyethylene terephthalate (PET), known within the textile industry as…

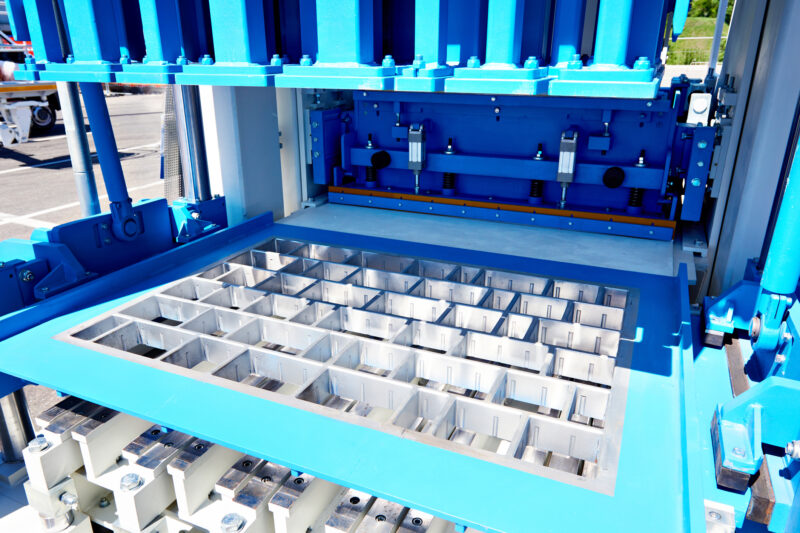

Read MoreA Compression Mold vs. Injection Mold: Which Is Right for You?

Plastic is one of the most-used materials for creating large numbers of consumer products. In addition, many industries use plastic components as substitutes for their metallic counterparts. As a result, numerous techniques for producing plastic materials are also emerging, though the most popular methods remain creating compression molds and injection molds. Plastic is one of…

Read MoreThe Sustainability Pros and Cons of Plastic Moulding

Injection plastic moulding is an efficient and sustainable manufacturing method that produces high-quality products, reduces waste and greenhouse gas emissions, and helps to clean up nature while improving a brand’s reputation through eco-friendly practices. Read on for more! The injection plastic moulding industry is improving almost every year by offering a more environmentally friendly process…

Read MoreWhat Are the Steps to Injection Molding Plastic?

Read on to learn about injection molding plastic, which involves fabricating plastic components of varying complexity, sizes, and application. One of the popular methods for manufacturing plastic components is injection molding. This process, which is not overly complicated, is favored chiefly due to its tendency to facilitate extensive production runs of identical components. Moreover, it…

Read MoreCustom Blow Molding: Know Your Method Options

When it comes to custom blow molding, there are various method options to consider. That said, it’s helpful to learn the details about all of them. Read more below. The adoption of custom blow molding in PET bottle manufacturing is needed to create uniform or conforming hollow shapes in plastic bottles that are meant for…

Read MoreWhat Is the Difference Between Plastic Pellets, Granules and Other Polymer Materials?

Various processes have been used in the creation of plastics over the years. However, there is a difference between plastic pellets, granules, powder, and other polymeric materials that are formulated during the processing of polymer. These different forms of materials are also prepared to be fed into the machine the plastic will be created. First…

Read More