Compressor Parts

Diagnosing Valve Leakage: Which Compressor Parts to Inspect First

Valve leakage occurs when gas or fluid escapes past a compressor’s valves, reducing efficiency, increasing energy consumption, and causing potential system damage. Common causes include worn valves, damaged seals, or misaligned components. Prompt diagnosis, high-quality replacement parts, and regular maintenance are essential to prevent valve leakage and ensure reliable, efficient compressor operation. Valve leakage in…

Read MoreTop Materials Used in Modern Valve Repair Kits and Why They Matter

Valve repair kits contain essential components—such as seals, gaskets, and seats—designed to restore valves to peak performance. The materials used, including metals, plastics, and elastomers, determine durability, chemical resistance, and wear life. Choosing high-quality valve repair kits ensures reliable operation, minimizes downtime, and extends the lifespan of critical valve systems. Valve failures can lead to…

Read MoreCommon Gasket Seal Failures in Reciprocating Compressors and How to Avoid Them

A gasket seal is a vital component in reciprocating compressors, designed to prevent leaks, maintain pressure, and ensure reliable performance. When properly selected and maintained, a gasket seal improves efficiency and reduces downtime. Choosing the right materials and practices helps avoid failures that can disrupt industrial operations. When gasket seals fail inside reciprocating compressors, the…

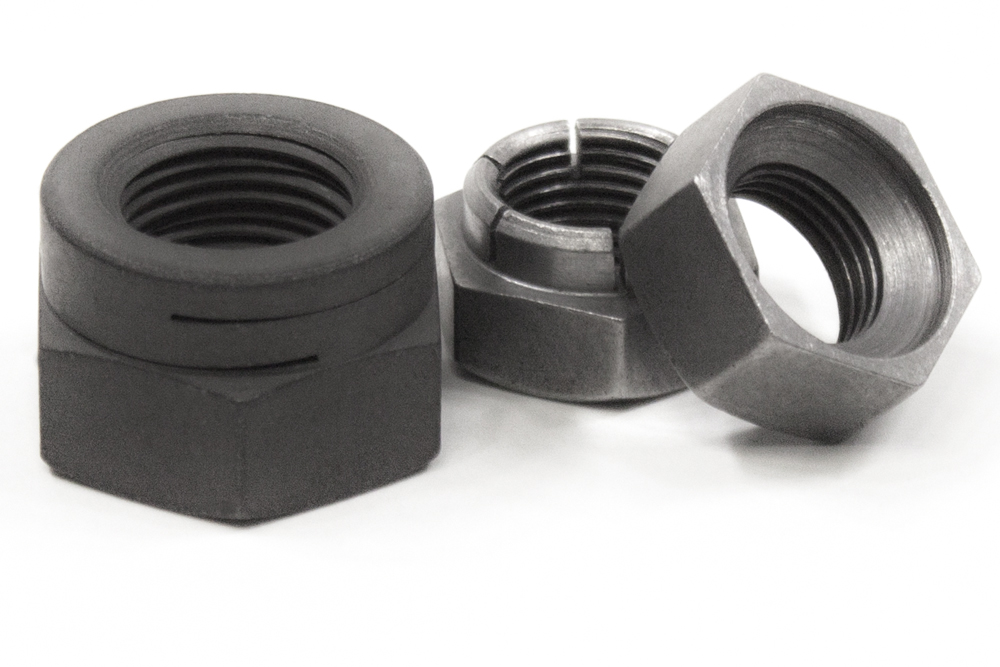

Read MoreSelecting the Proper Types of Locknuts for Safety and Reliability

Selecting the right types of locknuts is crucial for safety and reliability in industrial applications. Different locknut designs offer varying levels of vibration resistance, corrosion protection, and load capacity. Understanding their materials, threads, and performance characteristics ensures secure connections, reduces maintenance, and extends equipment lifespan across demanding operational environments. Ensuring safety and reliability in industrial…

Read MoreUnderstanding the Types of Washers in Reciprocating Compressor Maintenance

Different types of washers are essential in reciprocating compressor maintenance. Each type serves a specific purpose, from distributing loads to preventing vibration-related loosening. Choosing the right washer ensures proper alignment, reduces wear, and extends the life and efficiency of compressor components. Washer failure in reciprocating compressors may seem like a minor issue, but it often…

Read MoreTop Signs of Guide Ring Wear and When to Replace Them

A guide ring in reciprocating compressors plays a vital role in maintaining piston alignment and reducing lateral movement. By minimizing friction and wear between moving parts, guide rings help ensure efficient operation and prolong the life of the compressor. Timely inspection and replacement prevent costly damage and maintain optimal performance. Guide rings are critical components…

Read MoreStainless Steel Laser Cutting for OEM Precision Parts: What to Consider

Stainless steel laser cutting offers high precision, clean edges, and minimal material distortion, making it ideal for OEM precision parts. This method ensures repeatability and efficiency across complex designs and varying thicknesses. With fast turnaround and excellent surface quality, stainless steel laser cutting supports durable, high-performance components in demanding industrial applications. OEM manufacturers often face…

Read MoreGasket vs O-Ring: What’s the Difference and When to Use Each

Gasket vs O-ring: While both are essential sealing solutions, gaskets are ideal for flat, static surfaces, and O-rings work best in dynamic, pressurized environments with circular grooves. Choosing the right one depends on your application’s pressure, movement, and material needs—ensuring a proper seal, preventing leaks, and maximizing system performance. Sealing failures can lead to major…

Read MoreHow to Maintain Natural Gas Compressor Parts for Long-Term Performance

Natural gas compressor parts are critical components that ensure the efficient and safe operation of gas compression systems. Regular maintenance of valves, filters, seals, and fasteners helps prevent costly downtime and extends equipment lifespan. Using high-quality parts and monitoring system performance are key to achieving long-term reliability in natural gas applications. Neglecting routine maintenance of…

Read MoreHow Compressor Valve Peripherals Improve Performance and Efficiency

Compressor valve peripherals—such as springs, buttons, pins, washers, nuts, guide rings, and gaskets—are essential for maintaining optimal valve performance and efficiency. These small but vital components ensure proper alignment, sealing, and motion control, reducing wear and energy loss while extending the life of the entire compressor system. When compressor systems fall short of optimal performance,…

Read More