Compressor Parts

Stainless Steel Laser Cutting for OEM Precision Parts: What to Consider

Stainless steel laser cutting offers high precision, clean edges, and minimal material distortion, making it ideal for OEM precision parts. This method ensures repeatability and efficiency across complex designs and varying thicknesses. With fast turnaround and excellent surface quality, stainless steel laser cutting supports durable, high-performance components in demanding industrial applications. OEM manufacturers often face…

Read MoreGasket vs O-Ring: What’s the Difference and When to Use Each

Gasket vs O-ring: While both are essential sealing solutions, gaskets are ideal for flat, static surfaces, and O-rings work best in dynamic, pressurized environments with circular grooves. Choosing the right one depends on your application’s pressure, movement, and material needs—ensuring a proper seal, preventing leaks, and maximizing system performance. Sealing failures can lead to major…

Read MoreHow to Maintain Natural Gas Compressor Parts for Long-Term Performance

Natural gas compressor parts are critical components that ensure the efficient and safe operation of gas compression systems. Regular maintenance of valves, filters, seals, and fasteners helps prevent costly downtime and extends equipment lifespan. Using high-quality parts and monitoring system performance are key to achieving long-term reliability in natural gas applications. Neglecting routine maintenance of…

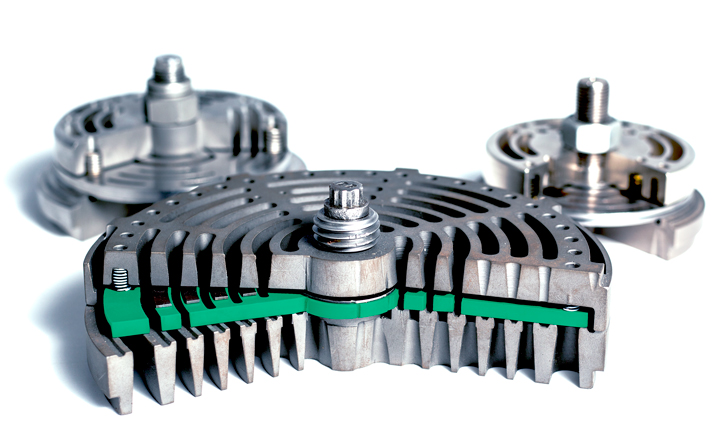

Read MoreHow Compressor Valve Peripherals Improve Performance and Efficiency

Compressor valve peripherals—such as springs, buttons, pins, washers, nuts, guide rings, and gaskets—are essential for maintaining optimal valve performance and efficiency. These small but vital components ensure proper alignment, sealing, and motion control, reducing wear and energy loss while extending the life of the entire compressor system. When compressor systems fall short of optimal performance,…

Read MoreUnderstanding the Causes of Compressor Valve Noise and How to Address It

Valve noise in compressors is a common sign of underlying issues such as worn components, improper alignment, or inadequate lubrication. Ignoring this noise can lead to decreased efficiency, increased energy consumption, and costly repairs. Addressing valve noise early can prevent further damage and ensure optimal compressor performance. Compressor valve noise is a common issue that…

Read MoreSigns Your Reciprocating Compressor Needs a Valve Rebuild

A valve rebuild is essential when a reciprocating compressor shows signs of wear, such as decreased efficiency, unusual noises, or pressure fluctuations. Rebuilding the valves restores proper sealing, improves performance, and reduces energy consumption, ultimately extending the lifespan of the compressor and preventing costly repairs. A reciprocating compressor is a critical component in many industrial…

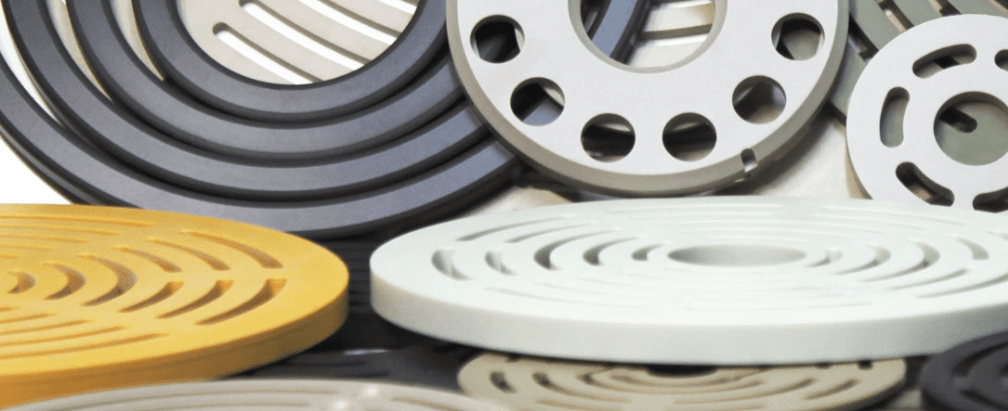

Read MoreThe Importance of Metallic Plates and Rings in Preventing Compressor Valve Wear

Metallic plates and rings are crucial in preventing compressor valve wear by reducing friction and providing a protective barrier. These components enhance valve durability, improve sealing efficiency, and extend the life of compressors. By minimizing wear, metallic plates and rings help maintain optimal performance and reduce the need for costly repairs. Compressor valve wear can…

Read MoreWhy Carbon PEEK is the Future of High-Performance Applications

Carbon PEEK (Polyetheretherketone) is a high-performance polymer known for its exceptional strength, thermal stability, and chemical resistance. Reinforced with carbon fibers, it outperforms traditional materials in demanding applications like medical devices, blow molding, and natural gas industries. Its durability, lightweight nature, and recyclability make it a future-proof choice for high-performance solutions. Introduction In today’s world,…

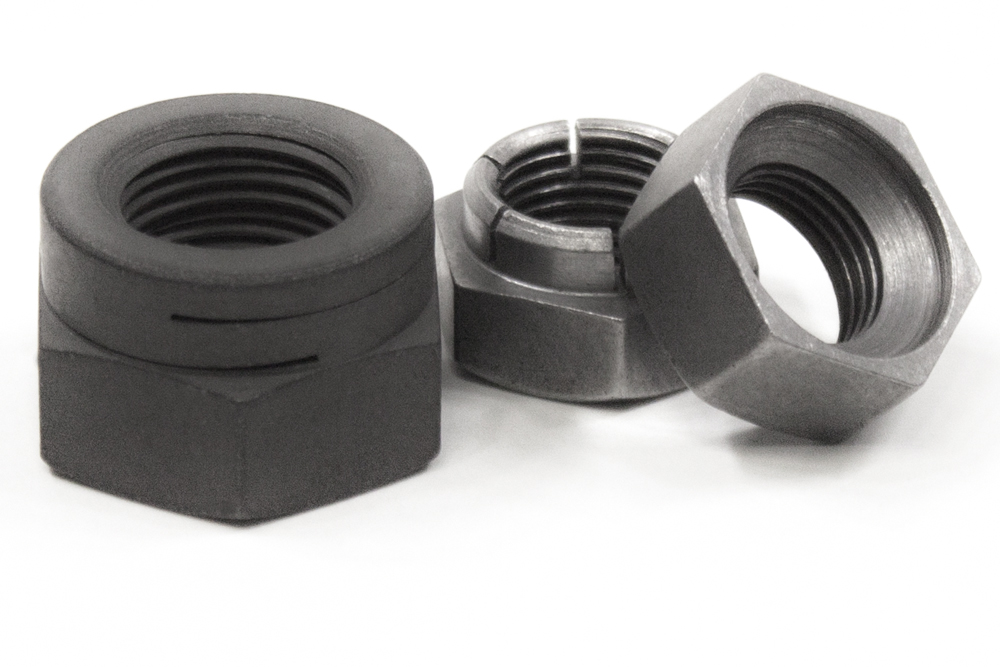

Read MoreWhat Are Locknuts and How Do They Work in Preventing Fastener Loosening?

Locknuts are specialized fasteners designed to prevent loosening due to vibrations, dynamic loads, and mechanical stress. With various types like nylon insert, prevailing torque, and serrated flange, they provide secure fastening in industries such as construction, aerospace, and manufacturing. Their durability and reliability make them essential for maintaining structural integrity in critical applications. Introduction Loose…

Read MoreHow Highest Grade Steel Enhances Valve Performance

The highest grade steel offers exceptional strength, durability, and resistance to corrosion, making it ideal for industrial valve applications. Its ability to withstand high temperatures and pressures ensures long-lasting performance, reducing maintenance and downtime. Investing in valves made from the highest grade steel enhances efficiency, safety, and cost-effectiveness across various industries. Introduction Valves play a…

Read More