Posts by admin

Sustainability in the P.E.T. Bottle Blowing Industry: Challenges and Opportunities

The P.E.T. bottle blowing industry plays a crucial role in producing lightweight, durable, and recyclable plastic bottles for beverages and other consumer goods. This industry focuses on efficiency and sustainability, using advanced technologies to mold P.E.T. (Polyethylene Terephthalate) into bottles, while also addressing environmental concerns through recycling and innovative manufacturing processes. The P.E.T. bottle blowing…

Read MoreHow Does a Reciprocating Compressor Operate?

A reciprocating compressor operates by using a piston within a cylinder to compress gas. As the piston moves down, it draws gas in, and as it moves up, it compresses the gas, increasing its pressure. This cycle repeats, making reciprocating compressors essential in many industrial applications for efficiently compressing gases. Understanding the inner workings of…

Read MoreUnderstanding the Natural Gas Compressor Station Design and Functionality

Natural gas compressor station design and functionality are crucial for efficient gas transportation. These stations boost gas pressure to ensure smooth flow through pipelines. Key components include compressors, cooling systems, scrubbers, and control systems. Proper design and regular maintenance enhance performance, safety, and environmental compliance, ensuring reliable and efficient gas distribution. Are you finding it…

Read MoreTechniques for Maximizing Compressor Valve Efficiency

Valve efficiency refers to the ability of a valve to perform its function with minimal energy loss and maximum effectiveness. High valve efficiency ensures optimal flow control, reduces energy consumption, and enhances the overall performance and reliability of mechanical systems. Efficient valves are crucial in industries such as oil and gas, manufacturing, and water treatment.…

Read MoreThe Different Types of Custom Injection Molding Processes

Custom injection molding processes are leading the way in modern manufacturing, providing unmatched precision and efficiency in producing complex and finely detailed components. These processes utilize advanced technology to achieve consistent results, meeting the exacting standards of diverse industries with ease. By delving into the nuances of injection molding, businesses can unlock new possibilities for…

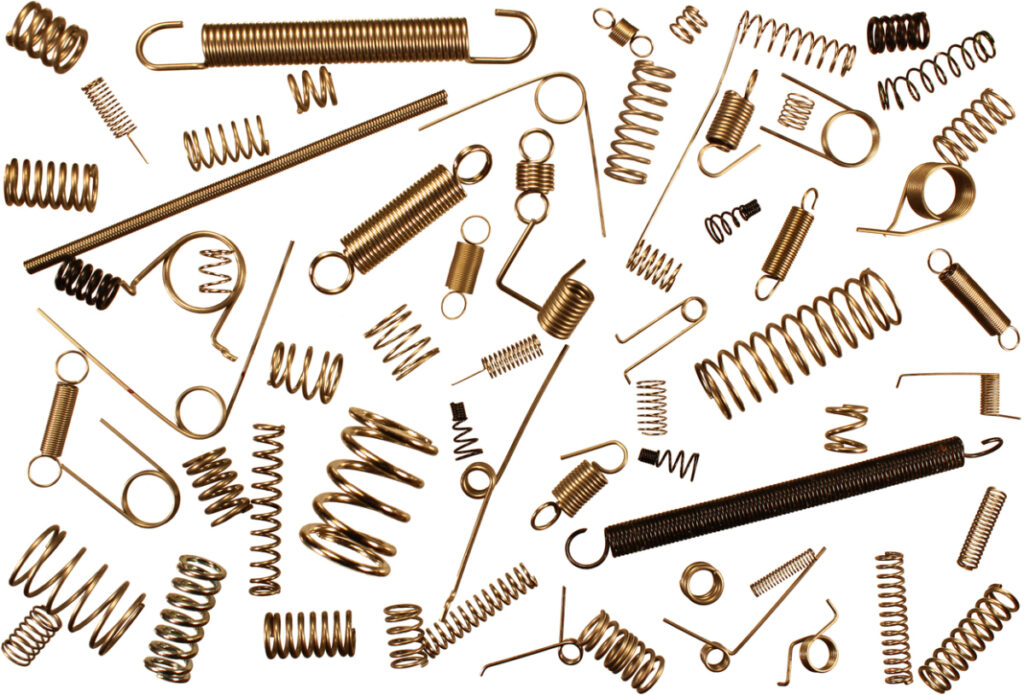

Read MoreDo Coil Springs Wear Out?

Yes, coil springs can wear out over time due to factors like stress, fatigue, and corrosion. Regular inspection and maintenance are crucial to prolong their lifespan and ensure optimal performance in mechanical systems. Proper care helps mitigate potential failures, preserving the efficiency and reliability of coil springs across various applications. Do coil springs wear out?…

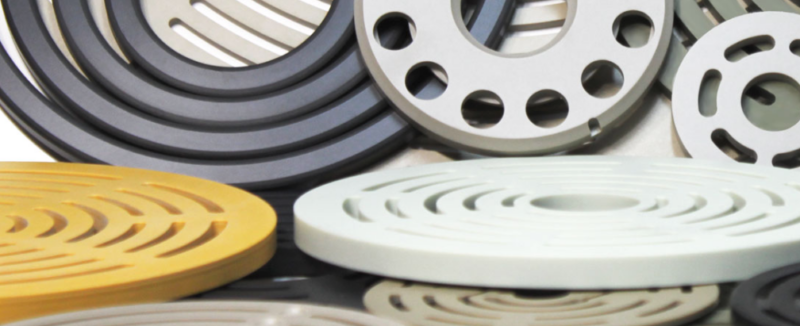

Read MoreWhat Are the Key Properties of Thermoplastic Valve Materials?

Thermoplastic valves have gained prominence as versatile and dependable components in various industries. Their remarkable properties have made them a preferred choice in applications ranging from water treatment to chemical processing. In this comprehensive guide, we will delve into the essential properties of thermoplastic valve materials, shedding light on their significance and exploring the wide…

Read MoreMaintain Peak Performance: Your Guide to Compressor Valve Replacement Parts

In the world of industrial machinery, maintaining peak performance is an absolute necessity. At the core of this endeavor are compressor valves, often underappreciated yet absolutely essential components that hold the key to optimal machinery operation. These valves serve as the gatekeepers, meticulously controlling the flow of fluids or gases within the machinery, striking the…

Read MoreThe Different Compression Spring Sizes to Know

In the realm of mechanical components, compression springs play a pivotal role, quietly delivering essential force across a diverse array of applications. While they may not frequently bask in the limelight, their undeniable influence permeates through various industries. To ensure your projects run smoothly and efficiently, it is paramount to have a firm understanding of…

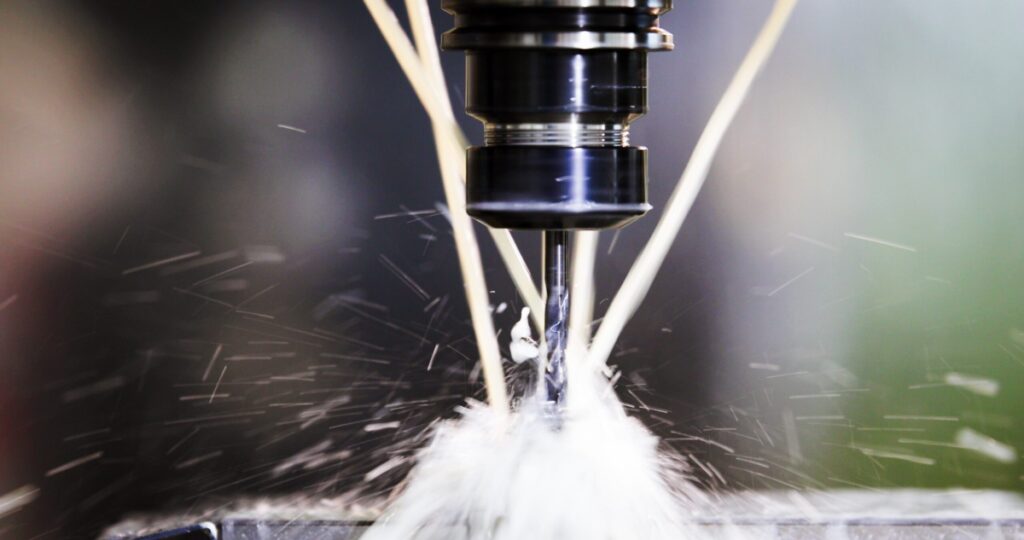

Read MoreWhat is a CNC Mill and Its Importance in Manufacturing Compressor Parts

In the realm of contemporary manufacturing, success hinges upon the twin pillars of precision and efficiency. Central to achieving these objectives is the technology known as Computer Numerical Control (CNC) milling. Although a CNC mill may not commonly feature in everyday discussions, grasping its significance is imperative for streamlining production processes. The journey into the…

Read More