In the realm of mechanical components, compression springs play a pivotal role, quietly delivering essential force across a diverse array of applications. While they may not frequently bask in the limelight, their undeniable influence permeates through various industries. To ensure your projects run smoothly and efficiently, it is paramount to have a firm understanding of the intricate world of compression spring sizes.

Throughout this comprehensive article, we embark on a journey through the intricate landscape of compression springs, delving deep into their diverse sizes and their integral role in the domains of engineering and manufacturing. From aerospace to everyday consumer products, compression springs are the invisible force that ensures seamless functionality. By gaining insights into compression spring sizes, you equip yourself with the knowledge needed to optimize your projects, enhancing their performance, longevity, and reliability.

Empowering Industries

Compression springs, though often overlooked, are essential components in various industrial applications. These coiled springs excel in storing potential energy when compressed, releasing it when required to perform tasks across industries as diverse as aerospace, construction, and consumer goods. To harness their power effectively, it’s essential to acquaint yourself with the spectrum of compression spring sizes.

A Size for Every Need

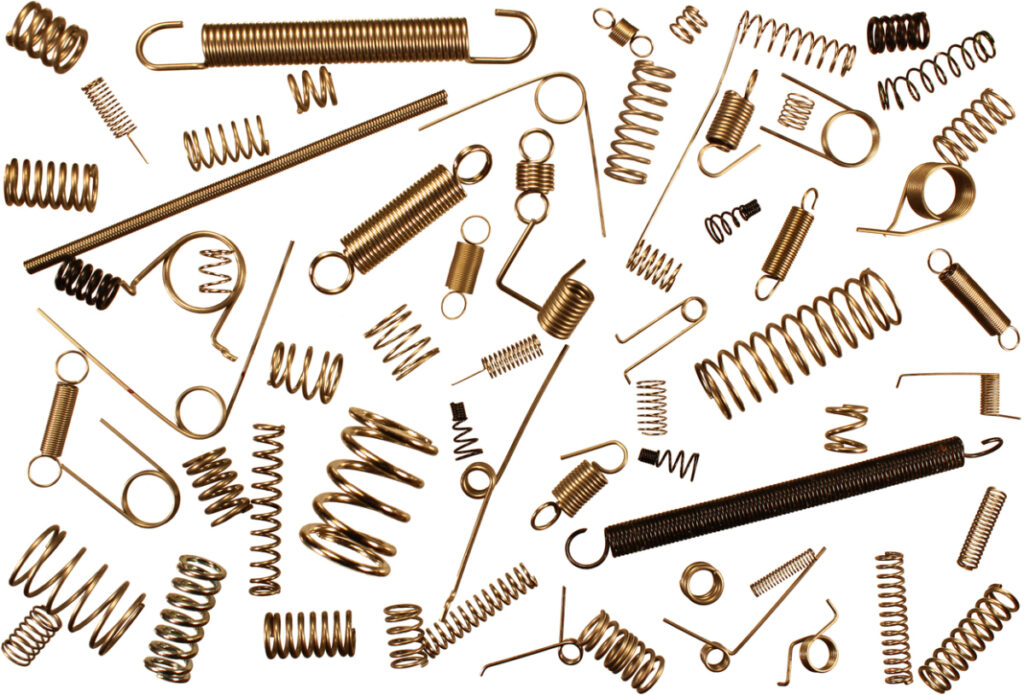

Compression springs offer a diverse spectrum of sizes, each intricately crafted to cater to distinct needs. These sizes range from the minuscule springs found within electronic devices to the robust counterparts that bear the weight of colossal machinery.

This impressive variety grants engineers and designers the valuable ability to fine-tune their applications with unparalleled precision, ensuring that each project meets its specific requirements impeccably. Making the right choice when it comes to size serves as the cornerstone for achieving peak performance and prolonged service life, and in the forthcoming sections, we will delve into the strategies for making these decisions with utmost effectiveness.

The Art of Size Selection

The choice of the right compression spring size stands as a pivotal decision in any project’s success. An inadequately sized spring can fall short in delivering the required force, while an oversized counterpart may subject your system to undue stress and premature wear, potentially jeopardizing your project’s longevity. To guarantee optimum efficiency, safety, and unwavering reliability, it is imperative to become proficient in the fine art of aligning compression spring sizes precisely with your application’s unique requirements.

By mastering this crucial skill, you empower yourself to create solutions that not only meet but exceed performance expectations, ensuring the smooth and enduring operation of your projects.

Key Factors Influencing Spring Sizes

The process of choosing the right compression spring size hinges on various vital factors:

- Load Requirements: Accurately determine the force or load the spring needs to exert or support within your application.

- Space Constraints: Assess the available space within your project to ensure the spring fits comfortably.

- Material Selection: Consider the material’s properties and their impact on the spring’s performance and longevity.

- Environmental Conditions: Account for factors such as temperature, corrosion, and other external elements that may affect the spring.

- Compression Ratio: Calculate the required compression or travel distance to achieve your project’s objectives effectively.

Understanding Compression Spring Sizing

To master the art of compression spring sizing, you need to understand the following key concepts:

- Wire Diameter: This is the thickness of the spring wire and plays a crucial role in determining the spring’s strength and durability.

- Outer Diameter: The outer diameter represents the total width of the compression spring.

- Inner Diameter: The inner diameter is the width of the spring’s central opening.

- Free Length: This is the length of the spring when it’s not under any load or compression.

- Solid Height: The solid height is the length of the spring when it’s fully compressed.

- Active Coils: These are the coils of the spring that actively participate in storing and releasing energy.

- Rate or Spring Constant: The rate or spring constant defines how much force the spring exerts per unit of deflection.

Benefits of Proper Compression Spring Sizing

- Optimal Performance: Choosing the right size ensures that the spring performs its intended function effectively.

- Longevity: Proper sizing extends the spring’s lifespan, reducing the need for frequent replacements.

- Safety: The correct spring size prevents overloading and potential hazards.

- Efficiency: Well-sized springs enhance the overall efficiency of your applications.

Practical Applications of Compression Springs

Indeed, the real-world applications of compression springs span a breathtaking spectrum. In the aerospace industry, where precision and safety are non-negotiable, these springs play a pivotal role in mechanisms that ensure the flawless operation of aircraft, from landing gear systems to intricate control mechanisms. The construction sector relies on compression springs to provide the robust reliability necessary for the structural integrity of buildings and infrastructure, from towering skyscrapers to resilient bridges.

However, their influence extends far beyond these domains. Compression springs make everyday life more comfortable, with their presence felt in mattresses, allowing for restful slumber, and in the seamless operation of pens, facilitating the smooth flow of ink onto paper. They even find their place in life-saving medical devices, where precision and consistency are paramount, ensuring the reliability of devices like insulin pumps and prosthetic limbs. By understanding compression spring sizes, engineers and designers across these diverse fields can ensure the triumph of their projects, whether in the sky, on the ground, or in the comfort of our daily lives.

Conclusion

In summary, compression springs are the versatile bedrock upon which a multitude of industries stand. Understanding the nuanced variations in compression spring sizes stands as a pivotal stride toward ensuring triumph across a range of projects.

By meticulously aligning the spring’s size with the precise demands of your application, and taking into account the critical factors that influence this decision, you can expertly channel the formidable power of these mechanical wonders. This mastery not only bolsters the efficiency of your projects but also fortifies their reliability and safety, ensuring that your endeavors are characterized by seamless functionality, durability, and peace of mind. As you navigate the complex world of compression spring sizes, you propel your ventures toward a future marked by triumph and excellence.

Contact KB Delta for information about compressor valve parts, compressor valves, and compressor valve repair kits.