Posts by admin

How to Inspect and Maintain Reciprocating Compressor Rod Packing Effectively

Reciprocating compressor rod packing is a critical component that seals the piston rod, preventing gas or fluid leaks while maintaining system pressure. Proper inspection, lubrication, and maintenance ensure reliable performance, reduce wear, and extend equipment lifespan. Routine care minimizes downtime, enhances efficiency, and protects the overall integrity of compressor systems. Reciprocating compressors are vital in…

Read MoreSigns Your Cushion Plates Need Replacement in Industrial Compressors

Cushion plates are essential components in industrial compressors that absorb shock, regulate pressure, and protect moving parts from excessive wear. Regular inspection and timely replacement prevent leaks, vibration, and reduced efficiency. Using high-quality cushion plates ensures consistent performance, extends equipment lifespan, and minimizes costly downtime in industrial operations. Cushion plates are critical components in industrial…

Read MoreCommon Valve Gasket Issues and How to Avoid Them

A valve gasket is an essential component that creates a secure seal between mechanical surfaces, preventing leaks and maintaining system pressure. Proper selection, installation, and maintenance of valve gaskets help ensure reliable performance, reduce wear, and extend equipment lifespan. Regular inspection and high-quality materials minimize downtime and operational disruptions. Valve gaskets are critical components in…

Read MoreExpert Guide to Choosing the Right Stainless Steel Compression Springs

Stainless steel compression springs are durable, corrosion-resistant components designed to withstand repeated compressive forces while maintaining consistent performance. Ideal for demanding environments, they offer reliable load support, fatigue resistance, and long service life. Choosing the right specifications ensures optimal efficiency, stability, and long-term mechanical reliability across a wide range of applications. Selecting the wrong spring…

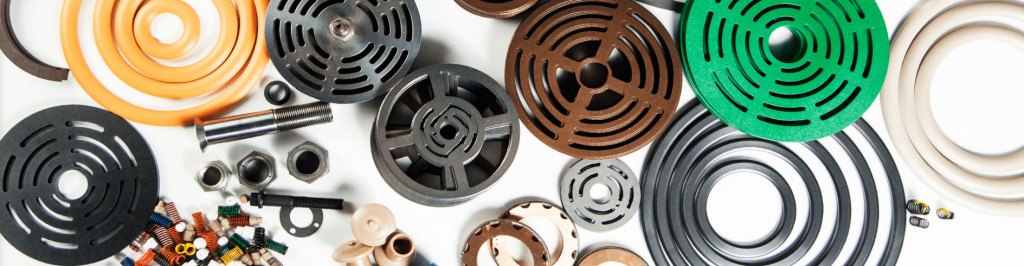

Read MoreAftermarket Parts for Compressors: What Operators Should Know

Aftermarket parts for compressors provide operators with cost-effective, readily available replacements that help maintain system performance and uptime. High-quality components can match operational requirements while reducing downtime and supporting long-term equipment reliability. Choosing the right aftermarket parts ensures efficiency, durability, and predictable maintenance schedules. Unexpected component failures can bring operations to a halt, strain maintenance…

Read MoreMaximizing Efficiency in Natural Gas Compressor Systems

Maximizing efficiency in natural gas compressor systems is essential for reducing energy costs and maintaining reliable operation. Proper sizing, regular maintenance, and advanced control strategies ensure optimal performance. By addressing energy losses and implementing best practices, operators can extend equipment life and achieve consistent, cost-effective operation in their natural gas compressor systems. Natural gas compressor…

Read MoreTips for Specifying the Right Valve Parts for Your Compressor Model

Selecting the right valve parts is essential to keep your compressor model running efficiently and reliably. Matching material specifications, pressure ratings, and OEM compatibility ensures optimal performance and longevity. Properly specified valves prevent downtime, reduce wear, and maintain consistent operation for your compressor model under varying operating conditions. Selecting the right valve parts for your…

Read MoreReciprocating Compression: How It Works and Why It Matters

Reciprocating compression is a process where a piston moves back and forth within a cylinder to compress natural gas, converting mechanical energy into pressure energy. Widely used in industrial applications, it offers precise pressure control, high reliability, and adaptability. Proper understanding and maintenance ensure efficiency, longevity, and safe operation in demanding environments. Industrial and process…

Read MoreValve Seat Ring Materials and Applications

A valve seat ring ensures tight sealing and consistent flow control in valves used for compressors. Choosing the right valve seat ring material enhances corrosion resistance, reduces wear, and extends service life under demanding operating conditions. Valve seat rings play a critical role in controlling gas flow within a system by providing a reliable sealing…

Read MoreHow a P.E.T. Compressor Works, and Key Valve Parts to Stock

A P.E.T. compressor is designed to efficiently compress gases for industrial applications, ensuring consistent pressure and reliable operation. Its performance depends on well-maintained components, particularly valves, which control gas flow during compression cycles. Proper maintenance and stocking of key parts enhance durability, reduce downtime, and optimize system efficiency. Understanding how a P.E.T. compressor operates is…

Read More