Posts Tagged ‘Blow Molding’

Blow Molding Products: Innovating with Custom Designs and Materials

Blow molding products offer exceptional flexibility in design and material selection, making them ideal for creating custom, high-performance items across industries. From packaging to medical applications, this manufacturing process enables precise, lightweight, and durable products that meet specific needs. Innovation in blow molding continues to drive efficiency and product customization. In today’s fast-paced manufacturing environment,…

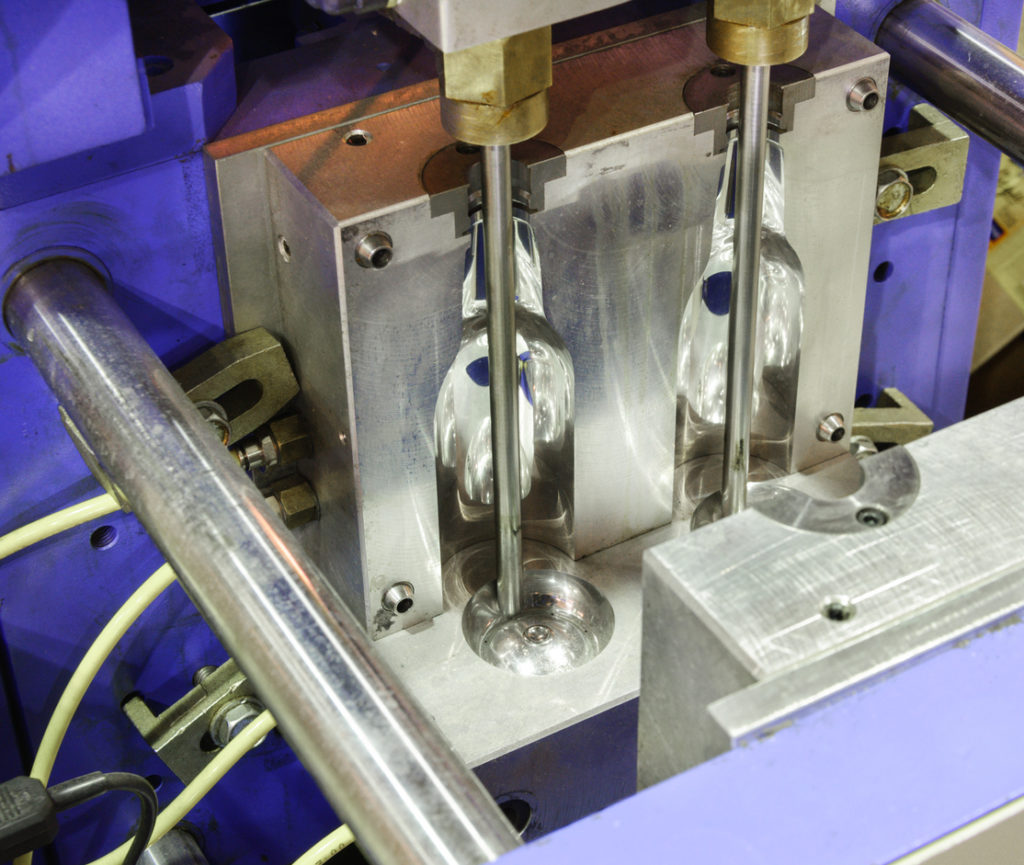

Read MoreStretch Blow Molding In the P.E.T Industry: What to Know

Stretch blow molding is the plastic process you never knew you appreciated. Here’s why this process is so important in bottle manufacturing. The P.E.T industry is often ignored even though it is all around people every day. Plastics are used for packaging food, drinks, medicines, and a variety of other products. There are projections that…

Read MoreUnderstanding Extrusion Blow Molding (EBM)

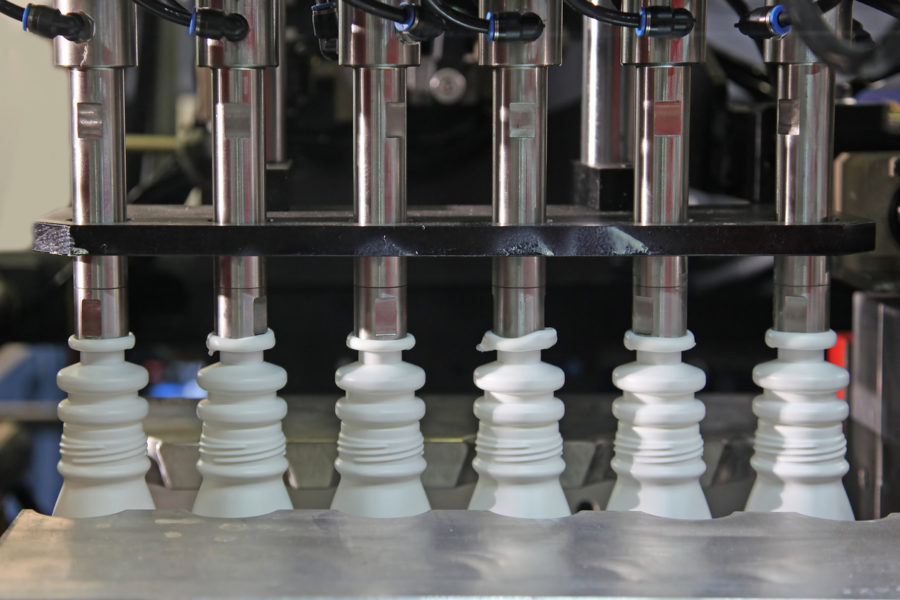

Have you ever seen a person at the fair or at the mall during the holidays, blowing glass to create beautiful, artistic designs? It’s mesmerizing how a random piece of colored glass can be manipulated by precisely placed hot air and become such a masterpiece. This art form actually inspired the current method of manipulating…

Read MoreWhat Is the Blow Molding Process in the Plastic Industry?

Blow molding is a type of manufacturing and production process that allows for the forming of hollow plastic parts. Air pressure is traditionally used to inflate a soft plastic into the mold cavity. While this technology originally derived from the glass industry, the blow molding process in the plastic sector competes in the recyclable and…

Read MoreHow to Avoid Equipment Failures in the Blow Molding Industry

Within the modern blow molding industry, there’s a constant push to find an edge over the competition. It’s the smallest of components that can hold the key to a businesses success. There is, of course, many different processes involved within the whole of the blow molding industry, such as injection, stretch, and intrusion. Each of…

Read MoreTwo Methods of the Blow Molding Process

What is Blow Molding? Blow molding is a process in manufacturing that creates hollow or shaped thermoplastic parts from a melting pot of polymer. The processes always begin with the polymer being melted down so that the machine can pull from the vat and inject the polymer into molds. These molds will allow the polymer…

Read More