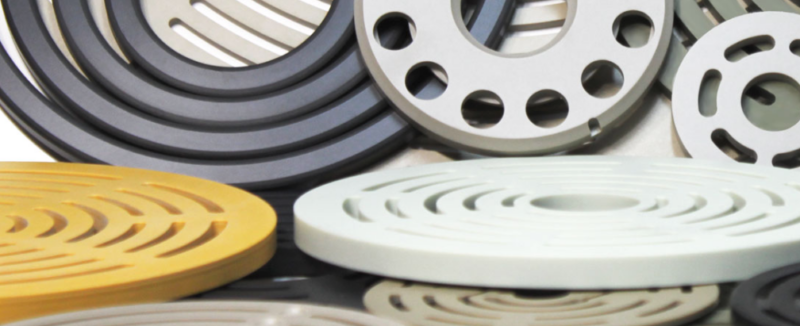

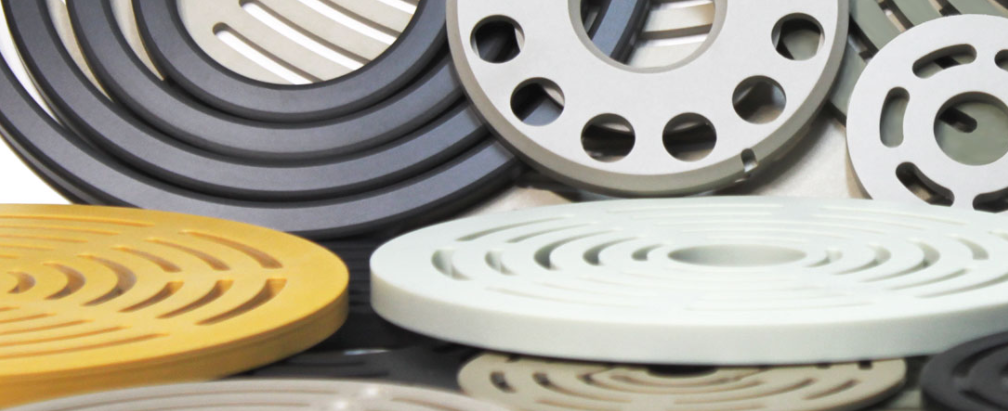

Thermoplastic Parts

Milling Process Explained: Manufacturing Thermoplastic Compressor Valve Parts

The milling process is a precision manufacturing method used to shape and finish materials by removing excess material with rotary cutters. In producing thermoplastic valve parts, it ensures accurate dimensions, smooth surfaces, and tight tolerances. Proper control of cutting parameters, tool selection, and heat management is essential for consistent, high-quality results. Manufacturing thermoplastic compressor valve…

Read MoreWhy Carbon PEEK is the Future of High-Performance Applications

Carbon PEEK (Polyetheretherketone) is a high-performance polymer known for its exceptional strength, thermal stability, and chemical resistance. Reinforced with carbon fibers, it outperforms traditional materials in demanding applications like medical devices, blow molding, and natural gas industries. Its durability, lightweight nature, and recyclability make it a future-proof choice for high-performance solutions. Introduction In today’s world,…

Read MoreWhat Is PET Material? Exploring Its Properties and Applications

What is PET material? PET (Polyethylene Terephthalate) is a strong, lightweight, and recyclable plastic widely used in packaging, textiles, and industrial applications. Known for its durability, clarity, and resistance to moisture, PET is a preferred choice for food containers, beverage bottles, and synthetic fibers. Its recyclability makes it an environmentally friendly option in various industries.…

Read MoreWhat Are the Key Properties of Thermoplastic Valve Materials?

Thermoplastic valves have gained prominence as versatile and dependable components in various industries. Their remarkable properties have made them a preferred choice in applications ranging from water treatment to chemical processing. In this comprehensive guide, we will delve into the essential properties of thermoplastic valve materials, shedding light on their significance and exploring the wide…

Read MoreDefining Tensile Strength For PEEK Material

Polyetheretherketone, or PEEK, is a versatile high-performance polymer gaining immense popularity in various industries. One of its standout attributes is its impressive tensile strength. In this article, we will delve into the world of PEEK, exploring what tensile strength means for this material and how it influences its wide-ranging applications. Prepare to uncover the power…

Read MoreThe Advantages of Using Thermoplastic Components in Manufacturing

In today’s fast-paced manufacturing industry, the choice of materials for various components is critical to achieving optimal results in product performance, cost, and sustainability. Thermoplastic components have become increasingly popular in manufacturing due to their remarkable advantages over traditional materials like metal, wood, and glass. In this article, we will explore the advantages of using…

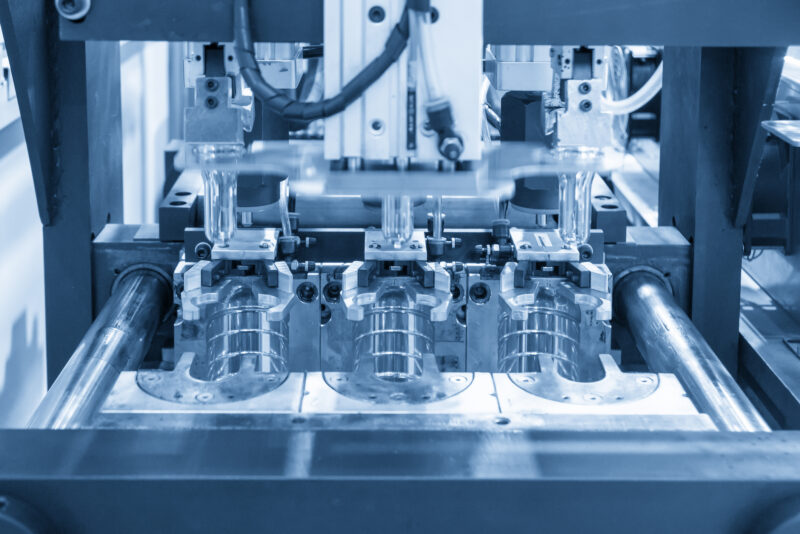

Read MoreInjection Molding Materials: Different Plastic Types and Applications

Injection molding is a manufacturing process involving injecting molten plastic into a mold to create various products. Different injection molding materials include Peek, Carbon Peek, Nylon 4,6, and Nylon 6,6. Continue reading for more. Injection molding is one of the most optimized and fastest methods of producing an incredibly high volume of identical and intricate…

Read MoreInjection Molding vs Blow Molding: What’s the Difference?

There are two distinct processes, injection molding vs blow molding, that play important roles in the custom manufacturing of disposable and reusable plastic components used in the biomedical, research, and medical diagnostic fields worldwide. Injection molding vs blow molding are two unique processes that have crucial roles in custom manufacturing disposable and reusable plastic components…

Read MoreWhat is Injection Molding Pressure?

Getting to know the details about injection molding pressure is key. Here’s a helpful guide. Many forms of pressure are actively involved in creating a plastic injection molded component. Why is this so important, you ask? Balancing the injection, back, and holding pressure correctly is crucial as this plays a significant role in consistently making…

Read MoreThe Process and Uses of Thermoplastic Nubs and Buttons

What’s important about thermoplastic nubs and buttons? Here’s information to keep in mind. Compressors are used across various industries, including oil and gas, metallurgical and engineering, etc. This makes them one of the most vital machines crucial to several production processes. This means that without compressors, many products or components in use today won’t be…

Read More