Manufacturing

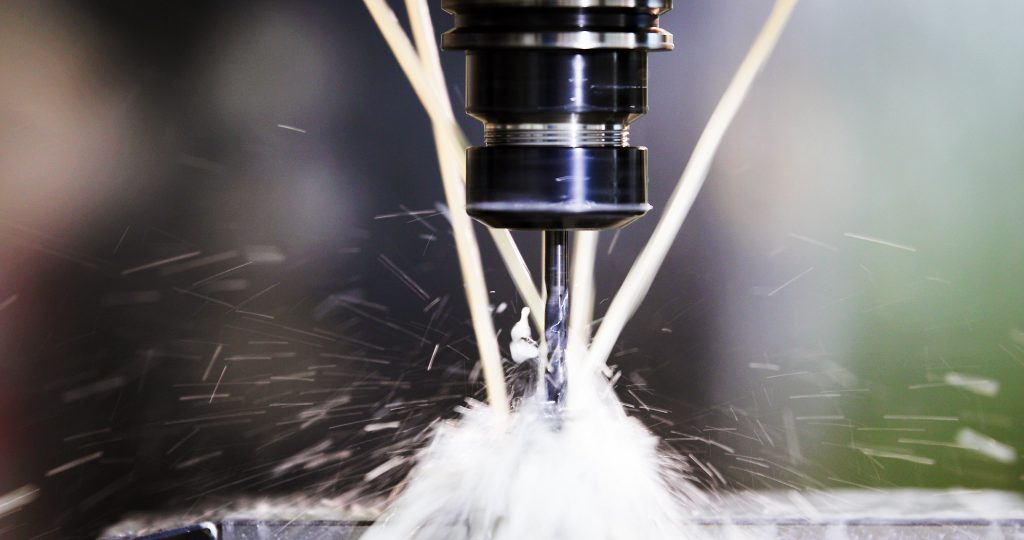

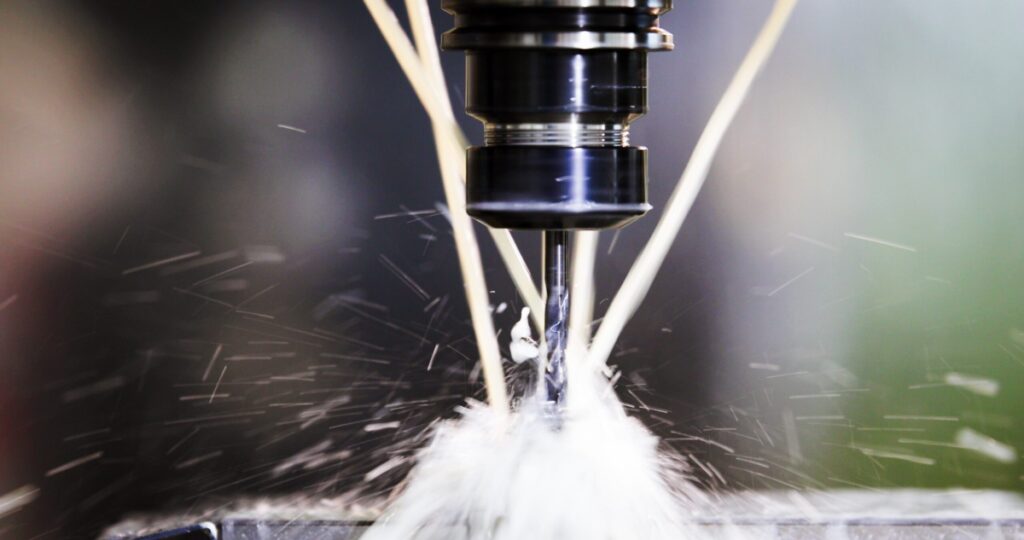

Milling Process Explained: Manufacturing Thermoplastic Compressor Valve Parts

The milling process is a precision manufacturing method used to shape and finish materials by removing excess material with rotary cutters. In producing thermoplastic valve parts, it ensures accurate dimensions, smooth surfaces, and tight tolerances. Proper control of cutting parameters, tool selection, and heat management is essential for consistent, high-quality results. Manufacturing thermoplastic compressor valve…

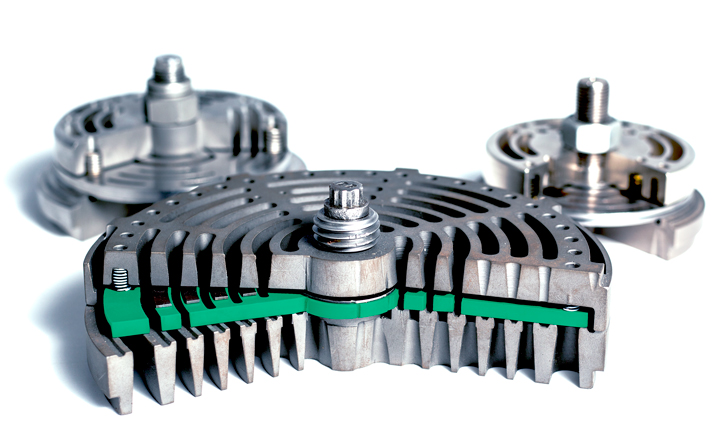

Read MoreWhy Compressive Force Matters When Sourcing Durable Compressor Parts

Compressive force is the pressure a material can withstand without deforming or failing under load. It plays a critical role in the durability and performance of industrial components, especially in high-pressure systems. Selecting parts with high compressive strength ensures long-lasting reliability, safety, and optimal function across demanding applications. Compressor failures often stem from overlooked technical…

Read MoreChoosing the Right Supplier for Your Spring Manufacturing Needs

Spring manufacturing involves the precise production of springs for a wide range of industrial applications. From material selection to coiling, heat treatment, and finishing, the process ensures durability, performance, and reliability. Choosing the right supplier is essential to meet design requirements, maintain quality, and support long-term operational success. Finding a trustworthy supplier for your spring…

Read MoreBlow Molding Products: Innovating with Custom Designs and Materials

Blow molding products offer exceptional flexibility in design and material selection, making them ideal for creating custom, high-performance items across industries. From packaging to medical applications, this manufacturing process enables precise, lightweight, and durable products that meet specific needs. Innovation in blow molding continues to drive efficiency and product customization. In today’s fast-paced manufacturing environment,…

Read MoreWhy Carbon PEEK is the Future of High-Performance Applications

Carbon PEEK (Polyetheretherketone) is a high-performance polymer known for its exceptional strength, thermal stability, and chemical resistance. Reinforced with carbon fibers, it outperforms traditional materials in demanding applications like medical devices, blow molding, and natural gas industries. Its durability, lightweight nature, and recyclability make it a future-proof choice for high-performance solutions. Introduction In today’s world,…

Read MoreWhat Do Spring Engineers Do and Why Are They Essential in Manufacturing?

Spring engineers are specialized professionals responsible for designing, testing, and producing springs used in various manufacturing applications. They ensure these components meet performance, durability, and safety standards, playing a critical role in product functionality. Their expertise in material selection, design, and testing ensures the efficiency and reliability of numerous products across industries. Introduction Spring engineers…

Read MoreHow Highest Grade Steel Enhances Valve Performance

The highest grade steel offers exceptional strength, durability, and resistance to corrosion, making it ideal for industrial valve applications. Its ability to withstand high temperatures and pressures ensures long-lasting performance, reducing maintenance and downtime. Investing in valves made from the highest grade steel enhances efficiency, safety, and cost-effectiveness across various industries. Introduction Valves play a…

Read MoreHow Metal Fabrication Helps Build Durable and Strong Structures

Metal fabrication involves shaping, cutting, and assembling metal materials into components and structures. It plays a critical role in construction, manufacturing, and various industries, offering strength, durability, and customization. By leveraging advanced techniques and sustainable practices, metal fabrication ensures efficient, precise, and eco-friendly solutions for modern engineering and design challenges. Introduction Building durable and strong…

Read MoreCompressor Thermodynamics Explained: Key Principles and Applications

Compressor thermodynamics explores the principles of pressure, volume, and temperature changes during compression. Understanding these processes—such as isothermal, adiabatic, and polytropic compression—enhances system efficiency, reduces energy loss, and ensures reliable performance. Proper thermodynamic analysis is essential for optimizing compressors in industrial, energy, and HVAC applications. Introduction Understanding compressor thermodynamics can feel overwhelming, especially when trying…

Read MoreWhat is a CNC Mill and Its Importance in Manufacturing Compressor Parts

In the realm of contemporary manufacturing, success hinges upon the twin pillars of precision and efficiency. Central to achieving these objectives is the technology known as Computer Numerical Control (CNC) milling. Although a CNC mill may not commonly feature in everyday discussions, grasping its significance is imperative for streamlining production processes. The journey into the…

Read More