High Quality Compression Springs and Wire Forms

With over 50 years of combined experience KB Delta recognizes the customer is what matters. We understand the spring is such a crucial component for the proper function of machinery and equipment. For this reason at KB Delta, our spring engineers develop a close personal relationship with our customers to determine which type of spring and which material best suits their needs. KB Delta has upheld its prominent reputation as a spring manufacturing innovator and leader by providing customers with high quality compression springs and on time delivery at the most competitive prices in the industry.

Springs are Available in Constant, Variable, Conical, Flat Wire, Tension/Extension, and Barrel Forms

Resource Data Sheets

Spring Types

Spring Identification Forms

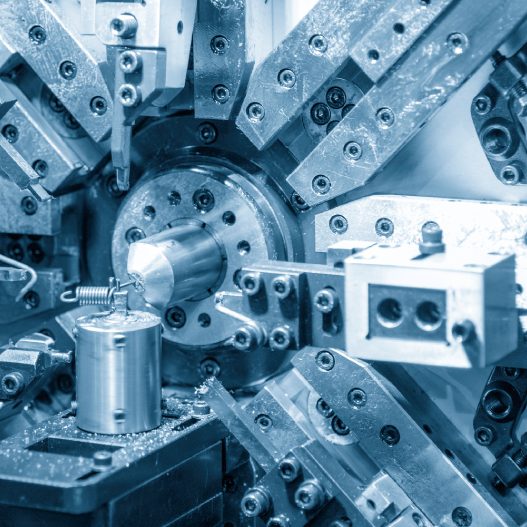

Our Process

The Right Spring Material

There is such a vast array of materials that it is imperative to determine the environment your spring or wire form will be operating in. Different environments require different materials and/or surface treatments. Factors that can affect your springs performance and lead to spring failure that must be considered are, the temperature your spring will be operating under and if the spring will be at risk of corrosion which are the most common causes of spring failure. KB Delta's team is skilled at working with an extensive host of materials and can help you to determine the right wire for your application. KB Delta is very proficient in working with the following materials; music wire, stainless steel, beryllium copper, Inconel, phosphor bronze, chrome silicon, Nimonic 90, Elgiloy, MP35, etc. with thicknesses ranging from .005" to .120".

Customization Process

If KB Delta stocks your spring or is provided spec sheets your spring will either be shipped out or put into production immediately. Otherwise mechanical and strength calculations are used to find a design of the spring which gives the spring performance you are expecting. We verify and validate the design by measuring and testing the important parameters that are important for your custom spring. KB Delta will also conduct stress analysis, force calculations, deflections, fatigue, capability studies will also be performed to determine the Cpk of the critical dimensions before placing your spring into production.

Our Capabilities

OEM STANDARDS

KB Delta is highly experienced in manufacturing Super Alloy Springs. Besides coiling KB Delta also offers heat treating, stress relieving, magnetizing, grinding, painting, and the metallic plating of your springs. KB Delta specializes in difficult to form flat wire compression springs in a variety of standard and exotic materials; Inconel X-750, Inconel 718, Nimonic 90, Hastelloy C-276, MP35N, Phynox (Elgiloy), Titanium (Grade 5), music wire, stainless steel, beryllium copper, Inconel, phosphor bronze, chrome silicon, Nimonic 90, Eligiloy, MP35, etc. with thicknesses ranging from .005" to .120". All springs meet or exceed OEM Standards and are RoHS compliant.

Constant Pitch Compression Springs

Variable Pitch Compression Springs

Conical Compression Springs

Flat wire Compression Springs *Minimum Order Requirement

Barrel/Tapered Compression Springs

Extension/Tension Springs

Many More Wire Forms

Industries We Serve

NATURAL GAS INDUSTRY