Understanding the Natural Gas Compressor Station Design and Functionality

Natural gas compressor station design and functionality are crucial for efficient gas transportation. These stations boost gas pressure to ensure smooth flow through pipelines. Key components include compressors, cooling systems, scrubbers, and control systems. Proper design and regular maintenance enhance performance, safety, and environmental compliance, ensuring reliable and efficient gas…

Techniques for Maximizing Compressor Valve Efficiency

Valve efficiency refers to the ability of a valve to perform its function with minimal energy loss and maximum effectiveness. High valve efficiency ensures optimal flow control, reduces energy consumption, and enhances the overall performance and reliability of mechanical systems. Efficient valves are crucial in industries such as oil and…

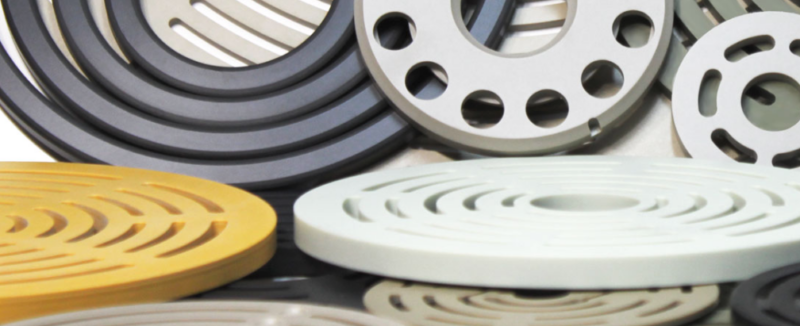

The Different Types of Custom Injection Molding Processes

Custom injection molding processes are leading the way in modern manufacturing, providing unmatched precision and efficiency in producing complex and finely detailed components. These processes utilize advanced technology to achieve consistent results, meeting the exacting standards of diverse industries with ease. By delving into the nuances of injection molding, businesses…

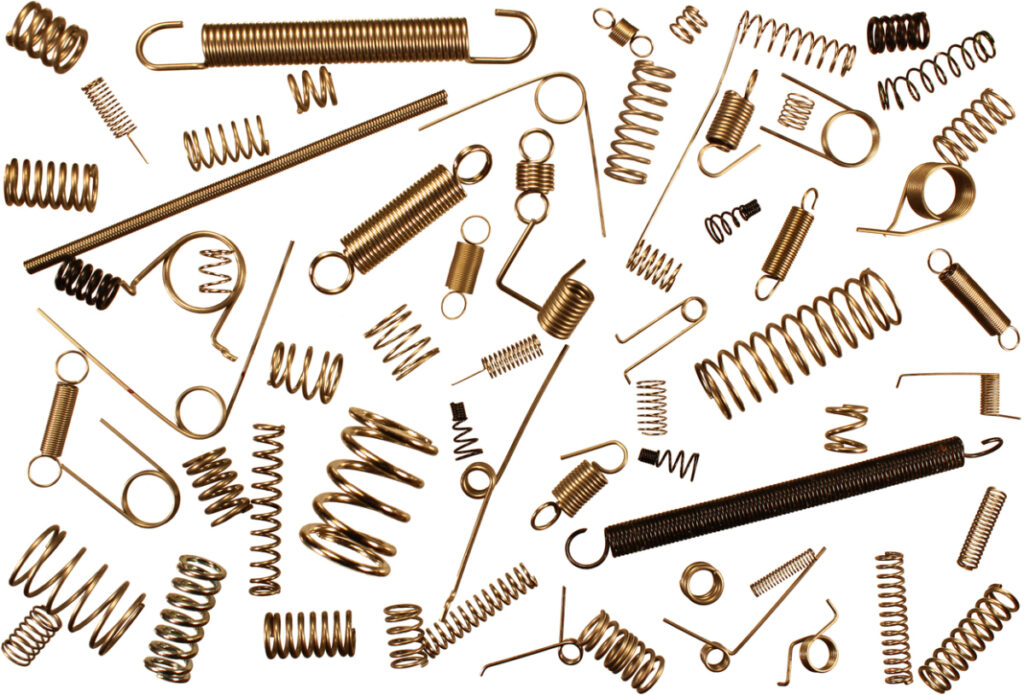

Do Coil Springs Wear Out?

Yes, coil springs can wear out over time due to factors like stress, fatigue, and corrosion. Regular inspection and maintenance are crucial to prolong their lifespan and ensure optimal performance in mechanical systems. Proper care helps mitigate potential failures, preserving the efficiency and reliability of coil springs across various applications.…

What Are the Key Properties of Thermoplastic Valve Materials?

Thermoplastic valves have gained prominence as versatile and dependable components in various industries. Their remarkable properties have made them a preferred choice in applications ranging from water treatment to chemical processing. In this comprehensive guide, we will delve into the essential properties of thermoplastic valve materials, shedding light on their…

Maintain Peak Performance: Your Guide to Compressor Valve Replacement Parts

In the world of industrial machinery, maintaining peak performance is an absolute necessity. At the core of this endeavor are compressor valves, often underappreciated yet absolutely essential components that hold the key to optimal machinery operation. These valves serve as the gatekeepers, meticulously controlling the flow of fluids or gases…

The Different Compression Spring Sizes to Know

In the realm of mechanical components, compression springs play a pivotal role, quietly delivering essential force across a diverse array of applications. While they may not frequently bask in the limelight, their undeniable influence permeates through various industries. To ensure your projects run smoothly and efficiently, it is paramount to…

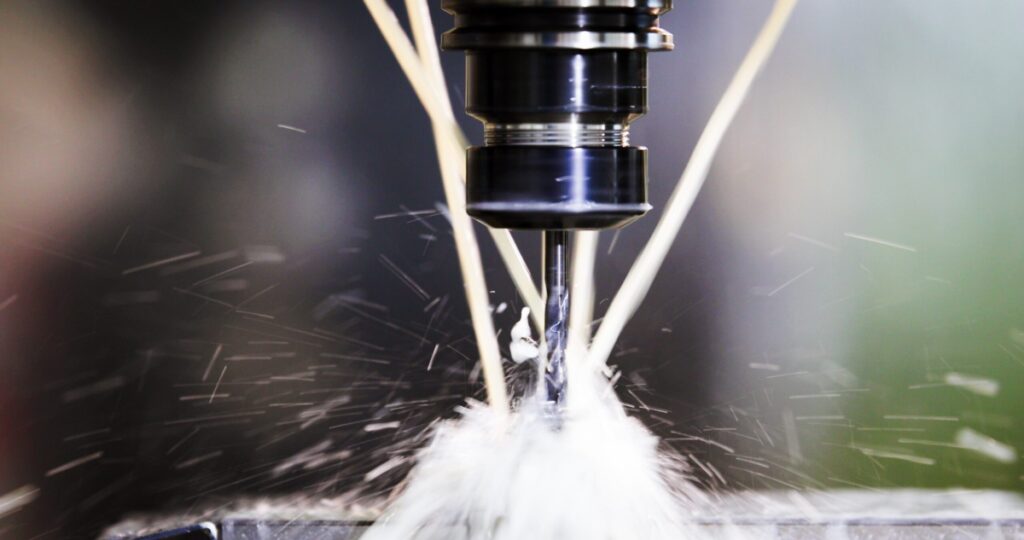

What is a CNC Mill and Its Importance in Manufacturing Compressor Parts

In the realm of contemporary manufacturing, success hinges upon the twin pillars of precision and efficiency. Central to achieving these objectives is the technology known as Computer Numerical Control (CNC) milling. Although a CNC mill may not commonly feature in everyday discussions, grasping its significance is imperative for streamlining production…

All About Gas Lift Compression in the Oil and Gas Industry

In the landscape of the oil and gas industry, achieving optimal production and extraction rates is paramount. To enhance the flow of hydrocarbons from reservoirs, various methods and technologies are employed. One such method that plays a crucial role in this endeavor is Gas Lift Compression. In this comprehensive guide,…

The Parts of a Piston Assembly and Its Key Role in Reciprocating Compressors

With reciprocating compressors, the piston assembly stands as a critical component that plays a pivotal role in the compression process. This intricate assembly is composed of various parts, each with its own specific function, working together seamlessly to enable the compressor to fulfill its essential purpose. In this article, we…