Valve seals are crucial components in various systems, helping to maintain efficiency and prevent unwanted leaks. Whether in industrial machinery, plumbing systems, or even household appliances, worn valve seals can lead to a range of issues.

In this article, we’ll help you understand the signs of worn valve seals, their impact on different systems, and the steps you can take to address these issues. By the end of this article, you’ll be equipped with the knowledge to identify and resolve worn valve seal problems, ensuring optimal valve performance in various applications.

The Importance of Valve Seals

Valve seals are often unsung heroes, quietly doing their job in a variety of systems. However, when these seals wear out, they can disrupt the functionality of essential equipment and systems. Whether you’re a homeowner or a professional in an industrial setting, recognizing the signs of worn valve seals is vital. Neglecting these issues can lead to reduced efficiency, leaks, and even damage to valuable equipment. In the following sections, we’ll delve into the telltale signs that indicate you may have worn valve seals and explore their consequences.

Identifying the Red Flags

Worn valve seals can manifest in various ways, depending on the system in which they are installed. It’s essential to be vigilant and recognize the red flags that may indicate valve seal issues. Whether it’s a household appliance, a plumbing system, or industrial machinery, understanding these signs is crucial for timely intervention. By addressing the red flags promptly, you can prevent further damage and maintain the efficiency of your systems.

Preventing Costly Consequences

Imagine the inconvenience and cost of a leaky plumbing system or the downtime and repair expenses associated with malfunctioning industrial machinery. The desire to prevent such consequences is what motivates individuals and professionals alike to learn how to identify depleted valve seals. By proactively addressing these issues, you not only save money but also ensure that your systems continue to operate optimally. The knowledge you gain from this article will empower you to take action and maintain the efficiency and reliability of your equipment.

Recognizing Signs of Worn Valve Seals

Now, let’s explore the actionable steps to recognize signs of worn valve seals in different systems. By paying attention to these indicators, you can take timely action to address the issue and prevent further damage.

Whether it’s a dripping faucet, a noisy industrial machine, or a malfunctioning household appliance, understanding these signs will enable you to pinpoint the problem and seek the necessary repairs or replacements.

- Leakage and Drips: One of the most common signs of worn valve seals is leakage. In plumbing systems, you may notice dripping faucets or pipes that won’t stop leaking. In industrial machinery, oil or fluid leaks can occur, leading to a messy and potentially hazardous work environment. Identifying and addressing these leaks promptly is essential to prevent water damage, product loss, or even safety hazards.

- Reduced Efficiency: Worn valve seals can compromise the efficiency of various systems. In appliances like refrigerators or air conditioners, reduced cooling efficiency may be noticeable. In industrial settings, machinery may operate less efficiently, leading to increased energy consumption and decreased production output. Recognizing these signs of reduced efficiency can help you take corrective measures to restore optimal performance.

- Noise and Vibration<: In some cases, worn valve seals can result in unusual noises and vibrations. This can be especially noticeable in industrial machinery, where excessive noise and vibration can indicate mechanical issues. Identifying and addressing these symptoms early can prevent further damage and minimize downtime.

- Temperature Fluctuations: Temperature control systems, such as those in household appliances or industrial processes, can be affected by worn valve seals. If you notice erratic temperature fluctuations or difficulties maintaining the desired temperature, it may be a sign of valve seal wear. Addressing these issues promptly is essential to ensure the proper functioning of these systems.

- Irregular Functionality: In some cases, worn valve seals can lead to irregular functionality. For example, in household appliances like washing machines or dishwashers, you may observe irregular cycles or incomplete operations. In industrial machinery, irregular functionality can result in inconsistent product quality or production delays. Recognizing these irregularities and investigating valve seal integrity is crucial for resolving the issue.

Conclusion

In conclusion, recognizing the signs of worn valve seals is essential for maintaining the efficiency and reliability of various systems. Whether in your home or workplace, understanding the impact and taking timely action can prevent costly consequences and ensure optimal performance.

By applying the knowledge gained from this article, you’ll be better equipped to identify and address worn valve seal issues, preserving the functionality of your equipment and systems.

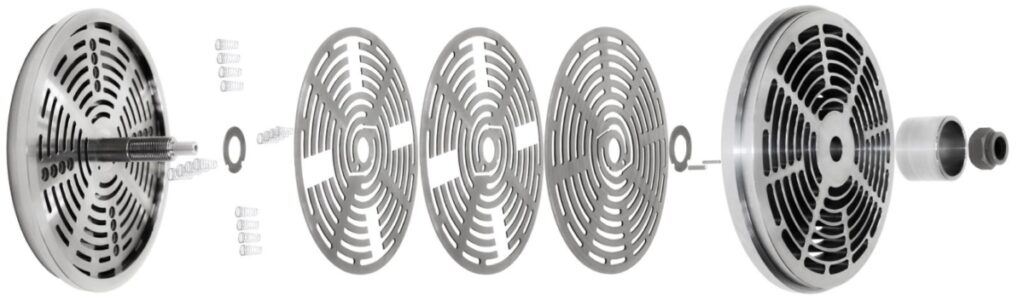

Contact KB Delta for compressor valve parts and more information about compressor valves, and compressor valve repair kits.